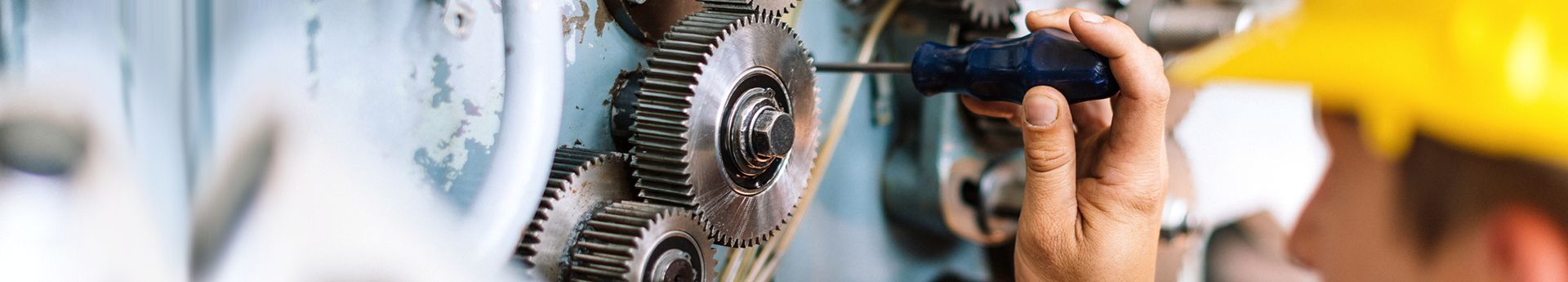

The

clutch release bearing seal has a unique variable contact design. It allows for maximum speed under maximum load. It is resistant to wear, has a long life and minimizes noise and vibration. In addition, its self-aligning design allows the clutch release bearing to control clutch condition and misalignment of clutch drive system components. Clutch release bearings also have a unique sealing system that isolates contaminants while retaining grease.

The first feature of the clutch release bearing:

1. Provide multiple mounting solutions for the two bearing rings by rolling the outer ring;

2. Elastic materials specially prepared according to the application speed and temperature requirements;

3. Excellent grease retention, friction reduction and excellent wear resistance throughout the life of the bearing;

The lip seals are designed with advanced materials and sealing lips to provide lower friction and good blowdown for extended life. You can choose to integrate a magnetic trigger wheel in the sealing system to provide a signal for the anti-lock brake system.

The second feature of the clutch release bearing:

1. Independent axial dust lip;

2. Radial sealing lip and grease lip;

3. Traditional sealing lip configuration;

4. Run the surface with a stainless steel oil slinger as a seal;

5. Elastic materials optimized for friction;

6. Low friction for reducing power loss and carbon dioxide emissions;

7. Achieve a long service life of the clutch release bearing by virtue of superior decontamination and residual grease capacity.

The third feature of the clutch release bearing:

1. A variety of seals lip design, such as lips, single lip. Excellent grease retention throughout the life of the bearing;

2. Bushings with rubber seals and ring gaskets for assembly;

3. A specially configured sealing lip with a PTFE coating on its surface;

4. Special assembly functions for different customer and service requirements. Easy to install and remove during maintenance.

Wheel Bearing

Wheel Bearing is a set of steel balls or rollers held together by a metal ring called a race. They help wheels spin fast with as little friction as possible. View More

Wheel Bearing

Wheel Bearing is a set of steel balls or rollers held together by a metal ring called a race. They help wheels spin fast with as little friction as possible. View More Wheel Bearing Kits

When you need to change the wheel hub bearing,you also need to replace many other parts at the same time,such as hub nut,bolt,seals,split pin,and so on. View More

Wheel Bearing Kits

When you need to change the wheel hub bearing,you also need to replace many other parts at the same time,such as hub nut,bolt,seals,split pin,and so on. View More Clutch Release Bearing

Clutch Release Bearing is what presses down on the rotating spring plate or "pressure plate" to release the clutch disk. View More

Clutch Release Bearing

Clutch Release Bearing is what presses down on the rotating spring plate or "pressure plate" to release the clutch disk. View More Belt Tensioner

A Drive Belt Tensioner is a pulley mounted to either a spring mechanism or to an adjustable pivot point that is used to keep constant tension on your serpentine belt. View More

Belt Tensioner

A Drive Belt Tensioner is a pulley mounted to either a spring mechanism or to an adjustable pivot point that is used to keep constant tension on your serpentine belt. View More Fuel Pump

AiX provide you with the high quality of electric fuel pump and fuel pump assembly.Fuel pump assembly is one of the vital components of fuel injection system for EFI vehicle. View More

Fuel Pump

AiX provide you with the high quality of electric fuel pump and fuel pump assembly.Fuel pump assembly is one of the vital components of fuel injection system for EFI vehicle. View More Water Pump

The reliable and effective operation of an automobile engine requires the cooperation of many parts. View More

Water Pump

The reliable and effective operation of an automobile engine requires the cooperation of many parts. View More Wheel Brake Cylinder

When you want your car to slow down or stop, you need to take the brake operation. At this point, you need to step down your brake pedal. View More

Wheel Brake Cylinder

When you want your car to slow down or stop, you need to take the brake operation. At this point, you need to step down your brake pedal. View More Crankshaft

Crankshaft is also known as crank.It is the important part of an engine to convert the up and down motion of the pistons into horizontal rotation.It is usually made by cast iron or forged steel. View More

Crankshaft

Crankshaft is also known as crank.It is the important part of an engine to convert the up and down motion of the pistons into horizontal rotation.It is usually made by cast iron or forged steel. View More VVT PHASER & OCV

VVT is the abbreviation of Variable Valve Timing. VVT PHASER is the vital component for the VVT engines. View More

VVT PHASER & OCV

VVT is the abbreviation of Variable Valve Timing. VVT PHASER is the vital component for the VVT engines. View More

+86-18758057736

+86-18758057736

TEAM 21,XIEJIA VILLAGE, PUYANG TOWN, XIAOSHAN DISTRICT, Hangzhou, Zhejiang Province, China

TEAM 21,XIEJIA VILLAGE, PUYANG TOWN, XIAOSHAN DISTRICT, Hangzhou, Zhejiang Province, China