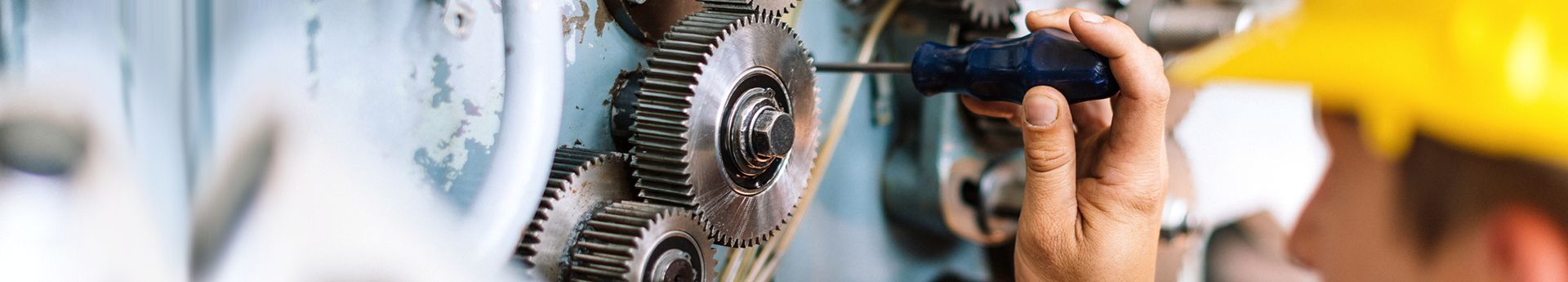

Wheel Hub

The development of wheel hub

The largest number of wheel hub bearings for cars used in the past was the use of single row tapered roller or ball bearings in pairs. With the development of technology, car wheel hub units have been widely used in cars. The range of use and usage of wheel hub bearing units has grown to the third generation: the first generation consisted of double row angular contact bearings, the second generation has a flange for fixing the bearing on the outer raceway, which can be simply fixed to the axle by a nut, making the maintenance of the car easier, and the third-generation wheel hub bearing unit is matched with a bearing unit and an anti-brake brake system, which the hub unit is designed with an inner flange and an outer flange. The inner flange is bolted to the drive shaft, and the outer flange mounts the entire bearing together.

The type of wheel hub

The hub is also called a rim. According to the characteristics and requirements of different models, the surface treatment process of the wheel hub will also adopt different methods, which can be roughly divided into baking varnish and electroplating. The wheel hub of the ordinary model is considered less in appearance, and the heat dissipation is a basic requirement. The process is basically painted with baking paint, that is, first sprayed and then baked, which making the cost relatively economical and the color is beautiful and the time is long. Even if the vehicle is scrapped, the color of the hub remains the same. Many Volkswagen models have a surface finish that is painted while some fashion-forward, sporty color wheels use paint technology. These wheels are affordable and come complete. Electroplated wheels are also divided into electroplated silver, water plating and pure plating. Although the electroplated silver and water electroplating wheels are bright and vivid, they are kept for a short time, so the price is relatively cheap, which is favored by many young people who are pursuing freshness. The market price is between RMB300 and RMB500. Purely plated wheels, color retention time is long, which can be said to be high quality and high price. Most high-end cars use purely plated wheels, and the price is about RMB800-900.

The manufacturing method of wheel hub

There are three manufacturing methods for aluminum alloy wheel hubs: gravity casting, forging, and low-pressure precision casting.

1. Gravity Casting Method: The aluminum alloy solution is poured into the mold by gravity, and after forming, it is processed by grinding on a la

the to complete the production. The manufacturing process which is relatively simple, does not require a precise casting process, having low cost and high production efficiency, but it is easy to generate bubbles (sand eyes), uneven density, and insufficient surface smoothness. Geely has a considerable number of models used in this way to produce the wheels, mainly in the early production models while the new models have been replaced with new wheel hubs.

2. Forging method: The whole piece of aluminum ingot is directly extruded on the mold by a thousand tons of press. The advantage is uniform density, smooth and fine surface, thin and light body of the hub, and the highest material strength, which is more than 30% higher than the casting method, but due to the need for better production equipment, and the yield is only fifty to sixty percent, the manufacturing cost is high.

3. Low-pressure precision casting method: Precision casting at a low pressure of 0.1Mpa, which has good formability, clear contour, uniform density and smooth surface. It can achieve high strength, light weight and cost control, and the yield is over 90%, which is the mainstream manufacturing method for high quality aluminum alloy wheel hubs.

Related News

June 30, 2018One specific thrust bearing in an automobile is the clutch "throw out" bearing, sometimes called the clutch release bearing.view

June 30, 2018One specific thrust bearing in an automobile is the clutch "throw out" bearing, sometimes called the clutch release bearing.view May 7, 2019The clutch release bearing is a relatively important part of the car. If the maintenance is not good, it will cause economic loss, and it takes a lot of labor to disassemble it once. Therefore, unders...view

May 7, 2019The clutch release bearing is a relatively important part of the car. If the maintenance is not good, it will cause economic loss, and it takes a lot of labor to disassemble it once. Therefore, unders...view May 15, 2019Wheel hub assembly bearing of the car was single row taper roller or ball bearing in pairs in the past.With the development of technology, car wheel hub assembly unit has been widely used in car. The ...view

May 15, 2019Wheel hub assembly bearing of the car was single row taper roller or ball bearing in pairs in the past.With the development of technology, car wheel hub assembly unit has been widely used in car. The ...view May 7, 2019The separation bearing is subjected to axial load, impact load and radial centrifugal force during high-speed rotation during use, and since the fork thrust and the reaction force of the separation le...view

May 7, 2019The separation bearing is subjected to axial load, impact load and radial centrifugal force during high-speed rotation during use, and since the fork thrust and the reaction force of the separation le...view May 7, 2019Generally speaking, the axle journal diameter is below 80mm, the crankshaft with the roundness and cylindricity error exceeds 0.025mm; or the axle journal diameter is above 80mm, the crankshaft with r...view

May 7, 2019Generally speaking, the axle journal diameter is below 80mm, the crankshaft with the roundness and cylindricity error exceeds 0.025mm; or the axle journal diameter is above 80mm, the crankshaft with r...view May 15, 2019In the use and installation of wheel hub assembly bearing, please pay attention to the following matters:1. In order to ensure maximum safety and reliability, it is recommended that you always check t...view

May 15, 2019In the use and installation of wheel hub assembly bearing, please pay attention to the following matters:1. In order to ensure maximum safety and reliability, it is recommended that you always check t...view

Wheel Bearing

Wheel Bearing is a set of steel balls or rollers held together by a metal ring called a race. They help wheels spin fast with as little friction as possible. View More

Wheel Bearing

Wheel Bearing is a set of steel balls or rollers held together by a metal ring called a race. They help wheels spin fast with as little friction as possible. View More Wheel Bearing Kits

When you need to change the wheel hub bearing,you also need to replace many other parts at the same time,such as hub nut,bolt,seals,split pin,and so on. View More

Wheel Bearing Kits

When you need to change the wheel hub bearing,you also need to replace many other parts at the same time,such as hub nut,bolt,seals,split pin,and so on. View More Clutch Release Bearing

Clutch Release Bearing is what presses down on the rotating spring plate or "pressure plate" to release the clutch disk. View More

Clutch Release Bearing

Clutch Release Bearing is what presses down on the rotating spring plate or "pressure plate" to release the clutch disk. View More Belt Tensioner

A Drive Belt Tensioner is a pulley mounted to either a spring mechanism or to an adjustable pivot point that is used to keep constant tension on your serpentine belt. View More

Belt Tensioner

A Drive Belt Tensioner is a pulley mounted to either a spring mechanism or to an adjustable pivot point that is used to keep constant tension on your serpentine belt. View More Fuel Pump

AiX provide you with the high quality of electric fuel pump and fuel pump assembly.Fuel pump assembly is one of the vital components of fuel injection system for EFI vehicle. View More

Fuel Pump

AiX provide you with the high quality of electric fuel pump and fuel pump assembly.Fuel pump assembly is one of the vital components of fuel injection system for EFI vehicle. View More Water Pump

The reliable and effective operation of an automobile engine requires the cooperation of many parts. View More

Water Pump

The reliable and effective operation of an automobile engine requires the cooperation of many parts. View More Wheel Brake Cylinder

When you want your car to slow down or stop, you need to take the brake operation. At this point, you need to step down your brake pedal. View More

Wheel Brake Cylinder

When you want your car to slow down or stop, you need to take the brake operation. At this point, you need to step down your brake pedal. View More Crankshaft

Crankshaft is also known as crank.It is the important part of an engine to convert the up and down motion of the pistons into horizontal rotation.It is usually made by cast iron or forged steel. View More

Crankshaft

Crankshaft is also known as crank.It is the important part of an engine to convert the up and down motion of the pistons into horizontal rotation.It is usually made by cast iron or forged steel. View More VVT PHASER & OCV

VVT is the abbreviation of Variable Valve Timing. VVT PHASER is the vital component for the VVT engines. View More

VVT PHASER & OCV

VVT is the abbreviation of Variable Valve Timing. VVT PHASER is the vital component for the VVT engines. View More

+86-18758057736

+86-18758057736

TEAM 21,XIEJIA VILLAGE, PUYANG TOWN, XIAOSHAN DISTRICT, Hangzhou, Zhejiang Province, China

TEAM 21,XIEJIA VILLAGE, PUYANG TOWN, XIAOSHAN DISTRICT, Hangzhou, Zhejiang Province, China