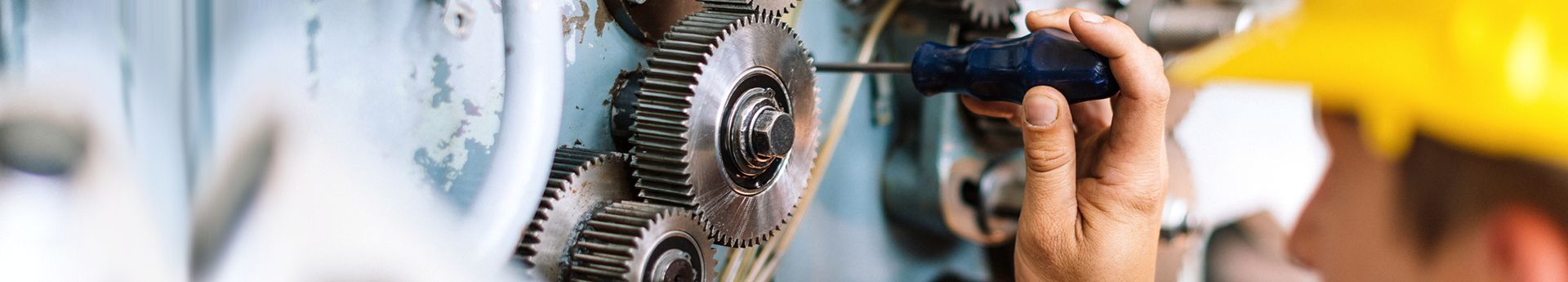

After repeated practice, improvement, and summing up experience, we finally formed a relatively simple method of oil injection operation. The specific process of extending the life of the

clutch release bearing is as follows:

(1) Oil filling method in which the engine does not disintegrate

First open the clutch cover and observe the wear of the clutch release bearing. If it is confirmed that the bearing is not damaged or the wear is not exceeded, remove the clutch pedal and adjust the connecting rod pin to return the split bearing and its seat to the final position. Fill the hole in the housing with a grease gun until the bearing overflows. Then turn the bearing a little and refill the oil. Repeat the above work until there is a little butter around the bearing, then turn the bearing and observe the amount of oil. If there is resistance to the rotation of the bearing, it is proved that the bearing is filled with butter. Then remove a small amount of butter that has spilled over the separation housing and reassemble the removed pin and clutch cover.

(2) Oil filling method for engine disintegration

Disassemble the engine to expose the assembly of the clutch release bearing and the housing. Use a grease gun to fill the small oil hole below the inner ring of the split housing. When the bearing has butter overflow, rotate the bearing until the bearing overflows with butter.

After the above two methods are processed, the bearings can be removed without oiling within half a year. After the trial of the oil filling method at Hengshui Railway Station, the mechanical integrity rate was significantly improved and significant economic benefits were achieved. Material costs can be saved. The machine has increased the loading and unloading capacity, and the loading and unloading capacity can be increased by 30t per unit per month. This method has also been promoted at other railway stations and has achieved satisfactory results.

Wheel Bearing

Wheel Bearing is a set of steel balls or rollers held together by a metal ring called a race. They help wheels spin fast with as little friction as possible. View More

Wheel Bearing

Wheel Bearing is a set of steel balls or rollers held together by a metal ring called a race. They help wheels spin fast with as little friction as possible. View More Wheel Bearing Kits

When you need to change the wheel hub bearing,you also need to replace many other parts at the same time,such as hub nut,bolt,seals,split pin,and so on. View More

Wheel Bearing Kits

When you need to change the wheel hub bearing,you also need to replace many other parts at the same time,such as hub nut,bolt,seals,split pin,and so on. View More Clutch Release Bearing

Clutch Release Bearing is what presses down on the rotating spring plate or "pressure plate" to release the clutch disk. View More

Clutch Release Bearing

Clutch Release Bearing is what presses down on the rotating spring plate or "pressure plate" to release the clutch disk. View More Belt Tensioner

A Drive Belt Tensioner is a pulley mounted to either a spring mechanism or to an adjustable pivot point that is used to keep constant tension on your serpentine belt. View More

Belt Tensioner

A Drive Belt Tensioner is a pulley mounted to either a spring mechanism or to an adjustable pivot point that is used to keep constant tension on your serpentine belt. View More Fuel Pump

AiX provide you with the high quality of electric fuel pump and fuel pump assembly.Fuel pump assembly is one of the vital components of fuel injection system for EFI vehicle. View More

Fuel Pump

AiX provide you with the high quality of electric fuel pump and fuel pump assembly.Fuel pump assembly is one of the vital components of fuel injection system for EFI vehicle. View More Water Pump

The reliable and effective operation of an automobile engine requires the cooperation of many parts. View More

Water Pump

The reliable and effective operation of an automobile engine requires the cooperation of many parts. View More Wheel Brake Cylinder

When you want your car to slow down or stop, you need to take the brake operation. At this point, you need to step down your brake pedal. View More

Wheel Brake Cylinder

When you want your car to slow down or stop, you need to take the brake operation. At this point, you need to step down your brake pedal. View More Crankshaft

Crankshaft is also known as crank.It is the important part of an engine to convert the up and down motion of the pistons into horizontal rotation.It is usually made by cast iron or forged steel. View More

Crankshaft

Crankshaft is also known as crank.It is the important part of an engine to convert the up and down motion of the pistons into horizontal rotation.It is usually made by cast iron or forged steel. View More VVT PHASER & OCV

VVT is the abbreviation of Variable Valve Timing. VVT PHASER is the vital component for the VVT engines. View More

VVT PHASER & OCV

VVT is the abbreviation of Variable Valve Timing. VVT PHASER is the vital component for the VVT engines. View More

+86-18758057736

+86-18758057736

TEAM 21,XIEJIA VILLAGE, PUYANG TOWN, XIAOSHAN DISTRICT, Hangzhou, Zhejiang Province, China

TEAM 21,XIEJIA VILLAGE, PUYANG TOWN, XIAOSHAN DISTRICT, Hangzhou, Zhejiang Province, China